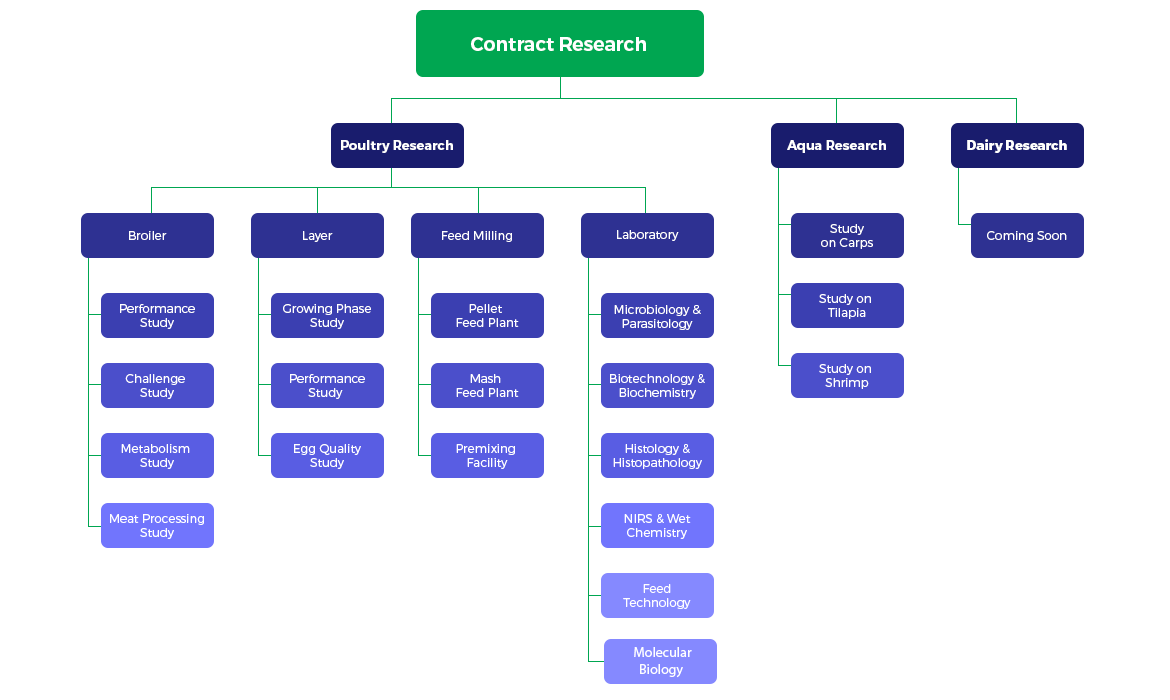

Poultry Research

Poultry Research

Performance trait (live weight, feed intake, feed conversion ratio, livability and

productivity index) measurement.

Performance trait (live weight, feed intake, feed conversion ratio, livability and

productivity index) measurement.

Cost of production and overall economics of production calculation.

Cost of production and overall economics of production calculation.

Three Broiler Houses with capacity to place 700, 640 and 400 birds.

Three Broiler Houses with capacity to place 700, 640 and 400 birds.

There are 70, 64 and 40 pens in each shed respectively.

There are 70, 64 and 40 pens in each shed respectively.

Three Broiler Houses with capacity to place 700, 640 and 400 birds.

Three Broiler Houses with capacity to place 700, 640 and 400 birds.

There are 70, 64 and 40 pens in each shed respectively.

There are 70, 64 and 40 pens in each shed respectively.

Broiler Performance Studies:

Broiler Performance Studies:

Options of conducting trials with straight run or all male flocks are available

Options of conducting trials with straight run or all male flocks are available

Bias is avoided by adopting completely randomized block designs in:

Bias is avoided by adopting completely randomized block designs in:

Distributing

chicks within pens

Distributing

chicks within pens  and pens

within a

house

and pens

within a

house Trials are undertaken for raw materials, complete feeds, feed additives, water soluble

medications, vaccines and for breed comparisons.

Trials are undertaken for raw materials, complete feeds, feed additives, water soluble

medications, vaccines and for breed comparisons.

Poultry Research

Poultry Research

A metabolism study room having controlled temperature is available for metabolism study.

A metabolism study room having controlled temperature is available for metabolism study.

The birds are put into specially designed metabolism cages where they are individually fed.

The birds are put into specially designed metabolism cages where they are individually fed.

The facility can conduct metabolism trials for major nutrients

The facility can conduct metabolism trials for major nutrients

either by

total

tract apparent digestibility method (faecal collection)

either by

total

tract apparent digestibility method (faecal collection) or by

apparent

ileal digestibility method involving markers (Celite, TiO2 or chromic oxide)

or by

apparent

ileal digestibility method involving markers (Celite, TiO2 or chromic oxide)

Drinking water is offered individually and is quantified. This facilitates the scope of

water medication studies.

Drinking water is offered individually and is quantified. This facilitates the scope of

water medication studies.

The Challenge Facility:

The Challenge Facility:

The objective of this facility is to simulate the actual field conditions in terms of :

The objective of this facility is to simulate the actual field conditions in terms of :

Environment: Heat or cold stress

Environment: Heat or cold stress

High

stocking

density

High

stocking

density

Exposure to

infective agents

Exposure to

infective agents

A separate complex with 32 pens of similar dimensions is available for such studies.

A separate complex with 32 pens of similar dimensions is available for such studies.

Pens are completely separated from each other in order to avoid cross contamination and

mixing of the birds/litter materials within the adjoining pens.

Pens are completely separated from each other in order to avoid cross contamination and

mixing of the birds/litter materials within the adjoining pens.

Designated exclusive workers work in this facility.

Designated exclusive workers work in this facility.

Equipment to induce thermal stress is available

Equipment to induce thermal stress is available

Stock culture of Eimeria spp. Clostridium perfringens, Salmonella and Escherichia

coli are available.

Stock culture of Eimeria spp. Clostridium perfringens, Salmonella and Escherichia

coli are available.

Specific ATCC strains can be arranged if requested for.

Specific ATCC strains can be arranged if requested for.

A group of poultry veterinarians assesses the load of challenge to be induced and if the

load looks ethically permissible then only challenge studies are undertaken. The main

objective is to abode by the ethical norms of the country and to prevent cruelty on the

experimental birds.

A group of poultry veterinarians assesses the load of challenge to be induced and if the

load looks ethically permissible then only challenge studies are undertaken. The main

objective is to abode by the ethical norms of the country and to prevent cruelty on the

experimental birds.

Meat Processing Study:

Meat Processing Study:

Semi-automatic broiler meat processing facility is in operation which measures yields of

dressed meat, internal organs and commercial cuts, chemical composition of meat, drip loss

and water holding capacity as well as cooking loss estimation.

Semi-automatic broiler meat processing facility is in operation which measures yields of

dressed meat, internal organs and commercial cuts, chemical composition of meat, drip loss

and water holding capacity as well as cooking loss estimation.

The details of the parameters which are measured are detailed out in the Agrivet Laboratory section

Overview of the facility:

Overview of the facility:

Layer birds are reared at DGN in California cages under open ventilation

system

aided by longitudinally mounted circulatory fans.

Layer birds are reared at DGN in California cages under open ventilation

system

aided by longitudinally mounted circulatory fans.

Cage dimension: 50 cm x 40 cm” x 40 cm approximately.

Cage dimension: 50 cm x 40 cm” x 40 cm approximately.

Space allocated per hen: 580 cm2

Space allocated per hen: 580 cm2

Lighting: Artificial + natural

Lighting: Artificial + natural

Feed form: mash or crumble whichever fits the study protocol.

Feed form: mash or crumble whichever fits the study protocol.

Water supply is through nipple drinker.

Water supply is through nipple drinker.

Parameters studied:

Parameters studied:

Body weight, feed intake and feed conversion ratio.

Body weight, feed intake and feed conversion ratio.

Egg production, egg weight and egg mass.

Egg production, egg weight and egg mass.

Egg grading

Egg grading

Egg shell thickness and breaking strength.

Egg shell thickness and breaking strength.

Yolk Colour scoring

Yolk Colour scoring

Measurement of Haugh unit

Measurement of Haugh unit

The details of the parameters which are measured are detailed out in the Agrivet Laboratory section

Pelleted feed manufacturing unit (capacity: 100kg/h)

Pelleted feed manufacturing unit (capacity: 100kg/h)

Mash feed manufacturing unit (capacity: 100kg/h)

Mash feed manufacturing unit (capacity: 100kg/h)

A precision premixing facility is available where additives in small

quantities are

added into the final batch following progressive dilution technique through

a 6 kg

and 20 kg fine mixer.

A precision premixing facility is available where additives in small

quantities are

added into the final batch following progressive dilution technique through

a 6 kg

and 20 kg fine mixer.

Vast choice of ingredients to formulate diets as per the need of research is

available.

Vast choice of ingredients to formulate diets as per the need of research is

available.

Pre-formulation analysis of ingredients for precision matrix correction is

the added

advantage.

Pre-formulation analysis of ingredients for precision matrix correction is

the added

advantage.

Proximate analysis of every batch of production is done to ensure quality

control.

Proximate analysis of every batch of production is done to ensure quality

control.

Study of Feed Production parameters:

Study of Feed Production parameters:

Pelleting parameters

Pelleting parameters

Pellet

Durability and hardness.

Pellet

Durability and hardness. Particle

size distribution analysis.

Particle

size distribution analysis. Measurement of pelleting throughput.

Measurement of pelleting throughput.

Measurement of power consumption ampere load, machine efficiency and other

parameters pertaining to pelleting equipment.

Measurement of power consumption ampere load, machine efficiency and other

parameters pertaining to pelleting equipment.

Agrivet laboratories are operated by competent technicians and are equipped aptly to

provide all the required services related to advanced livestock research.

Agrivet laboratories are operated by competent technicians and are equipped aptly to

provide all the required services related to advanced livestock research.

The laboratory has the following divisions:

The laboratory has the following divisions:

Microbiology

Microbiology

Biotechnology

and Biochemistry

Biotechnology

and Biochemistry  Pathology

and Parasitology

Pathology

and Parasitology NIRS

and

Nutrition Lab

NIRS

and

Nutrition Lab Feed

testing

Feed

testing  Overview of the parameters studied

Overview of the parameters studied

Raw

material analysis by NIR and wet chemistry.

Raw

material analysis by NIR and wet chemistry. Serum

assay

Serum

assay Histology/Histopathology

of internal organs

Histology/Histopathology

of internal organs Gross

organ morphometry

Gross

organ morphometry Rapid

toxin analysis by ELISA

Rapid

toxin analysis by ELISA  Immunology

and serology

Immunology

and serology  Aqua Research

Aqua Research

Aqua research facility is located at DGN

Aqua research facility is located at DGN

Tanks are circular with 400 lit water capacity

Tanks are circular with 400 lit water capacity

31 individual tanks allow the flexibility to conduct elaborate research

31 individual tanks allow the flexibility to conduct elaborate research

Following parameters can be generated from Production trials

Following parameters can be generated from Production trials

Total

biomass

production

Total

biomass

production Feed

conversion efficiency (FCE)

Feed

conversion efficiency (FCE) Average

daily

growth rate per tank

Average

daily

growth rate per tankComing Soon

© Agrivet Research & Advisory . All Rights Reserved | Design & Developed by DITS